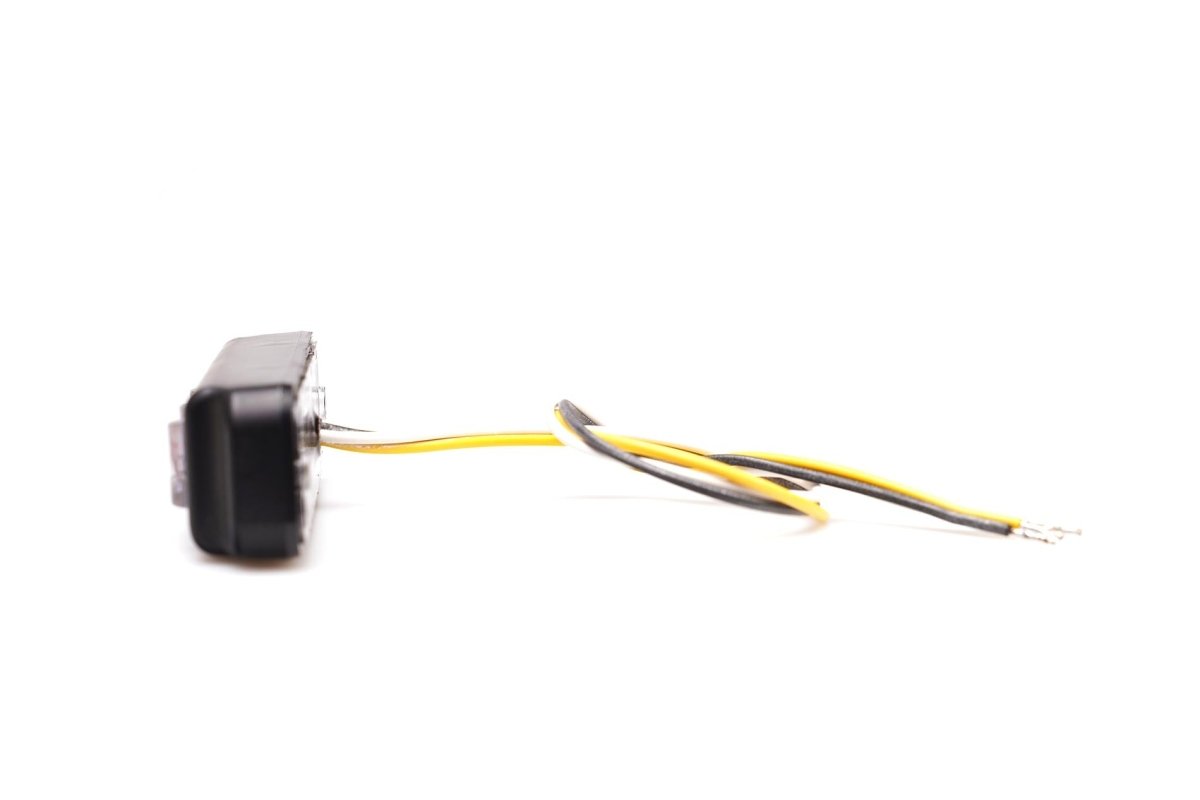

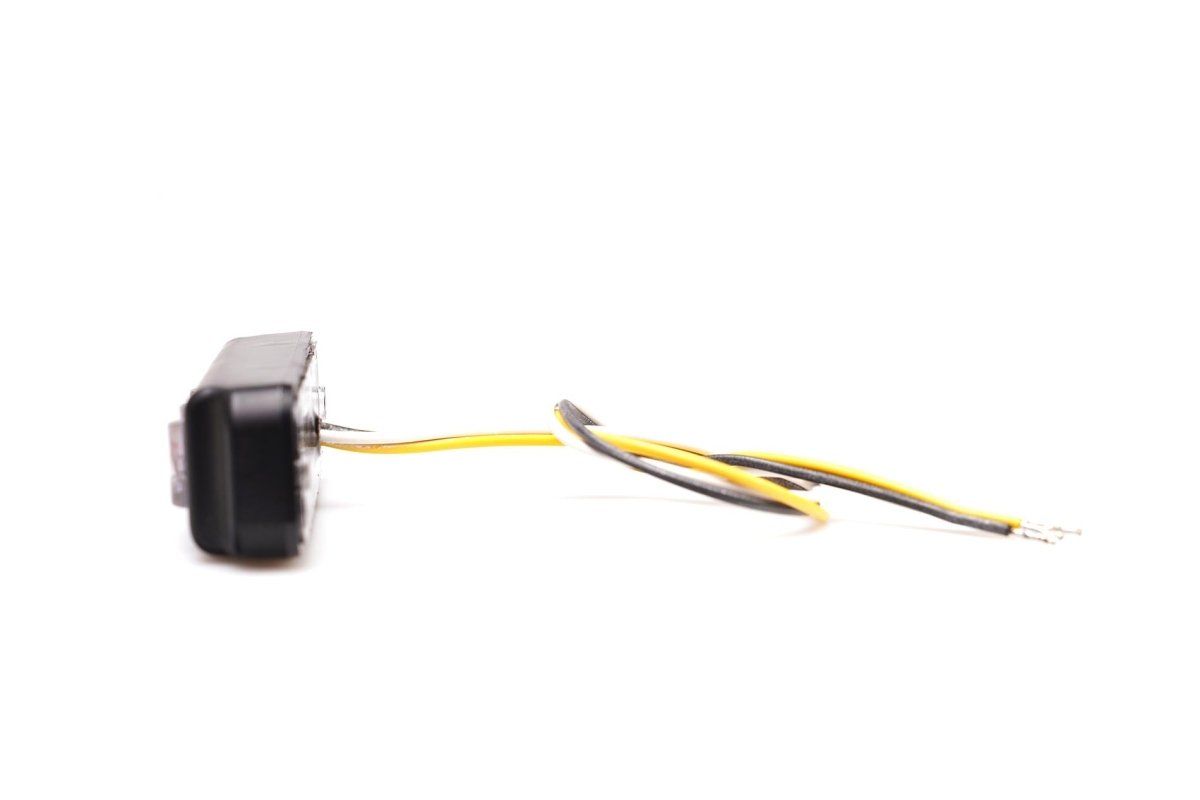

WAS W285 Series 20 LED hazard warning lamp

WAS W285 Series 20 LED hazard warning lamp

SKU:2466

WAS

Couldn't load pickup availability

- If you plan to install several lamps and synchronise them with each other, make sure that only one of them is connected as the ‘MASTER’. NOTE Only lamps of the same type and with the same number of patterns can be synchronised.

2. The Master, Slave function of the lamp is selected by connecting the white wire for the MASTER lamp or the yellow wire for the SLAVE lamp respectively to the (-) power supply of the vehicle.

3. The change of the synchronisation method to flashing in counter-phase is only possible to set in the SLAVE lamp(s), but without connection to the MASTER circuit.During operation of the SLAVE lamp(s), the white colour lead should be shorted to (-) of the power supply for about 5 seconds. The change will be confirmed by skipping one series of flashes. Shorting the white lead to (-) of the power supply again in SLAVE mode will set the lamp to synchronise in phase. All SLAVE lamps for which the phase of operation is to be changed can be switched together.

4. To change the pattern, short-circuit the synchronisation line for approximately 1 second to the (+) of the power supply. The MASTER lamp enforces the pattern number on the SLAVE lamps.

Specification

Specification

5 Flash patterns

IP69K ingress protection

Dual voltage

ECE R10 R65

Can be fitted horizontally or vertically

Can be synchronised

Dimensions 96 x 27.3 x 20mm LxWxD

Installation and care

Installation and care

To preserve the quality of your lights, do not utilise a pressure washer on a high setting.

The use of harsh cleaning chemicals can detrimentally effect the appearance and life of the product. Use warm soapy water and a wash brush or clean sponge to thoroughly clean front and back and rising to remove all soap.

With today’s high-quality lighting offering excellent dust and water sealing, lamp failures are rare. One common cause is water tracking through unsealed electrical connections, causing the copper core to blacken. Using waterproof plugs and sockets (superseals or Deutsch connectors) and adhesive heat-shrink sleeving and terminals can prevent this issue.

Additional Information

Additional Information

Product FAQ

Product FAQ

Shipping

Shipping

Orders placed before 1pm

Processed & shipped the same day unless otherwise stated.

Orders placed after 1pm

Processed & shipped the next working day.

Orders placed after 1pm on a Friday.

Processed & shipped the following Monday.

Orders are shipped Monday-Friday only.

Share